- Home

- Business Area

- About us

- Business Area

- PR

- Careers

- Contact

- VOCs Treatment Technology

- VOCs Treatment Technology

- ARECA Series

- PFCs Treatment Technology

- Application Guide

- Main References

- RCO

- RTO

- RCO

- FRTO

- CRTO

- CCO

- Waste Heat Recovery System

RCO (Regenerative Catalytic Oxidizer)

Description

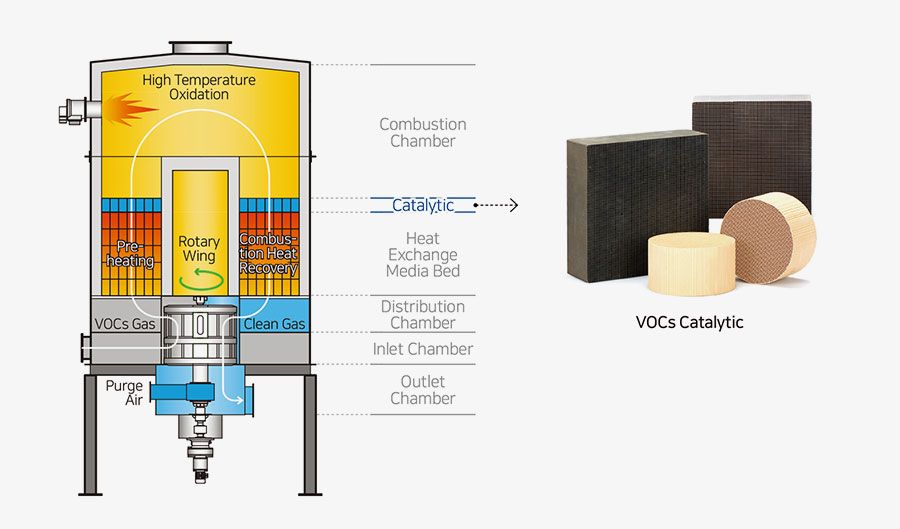

The regenerative catalytic oxidizer(RCO) initially heats the system by using a burner and then preheats the incoming VOCs gas. It is an economical system with low fuel cost by operating at combustion temperature as low as 200~400℃ when the inlet gas passes through oxidizable catalyst layer at low temperature.

This technology eliminates organic solvents and organic odors and prevents the air from being polluted by collecting and supplying heat by using the heat exchanger for heat exchange without discharging a considerable amount of combustion heat generated to outside atmosphere.

Features

- It can save fuel cost by recovering more than 95% of the heat from ceramic heat storage materials.

- Because it burns at low temperature, the amount of combustion NOx generated is relatively small.

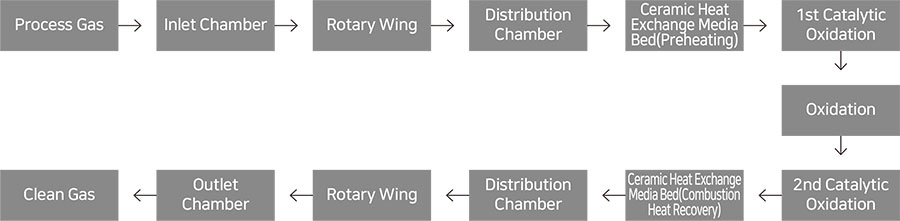

Process Flow Diagram

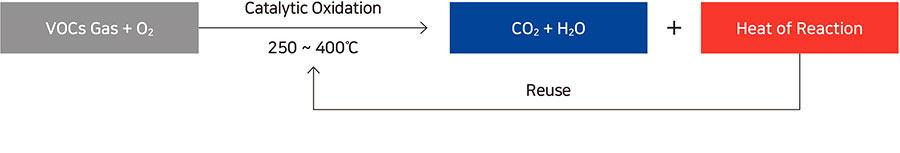

Reaction Mechanism

Application Scope

- Adhesives/Tape

- Automobile and steel

- Chemicals

- Films coating

- Food/Waste disposal

- LCD

- Paints

- Petrochemistry

- Plastics

- Plywood/Furniture

- Printing process

- Semi-conductor and display

- Steel furniture

- Synthetic resins

- Tires and tire cord fabrics

- Wallpaper/Dry materials

- Other VOCs & odor treatment and generated business places