- Home

- Business Area

- About us

- Business Area

- PR

- Careers

- Contact

- PFCs Treatment Technology

- VOCs Treatment Technology

- ARECA Series

- PFCs Treatment Technology

- Application Guide

- Main References

PFCs Treatment Technology

Description

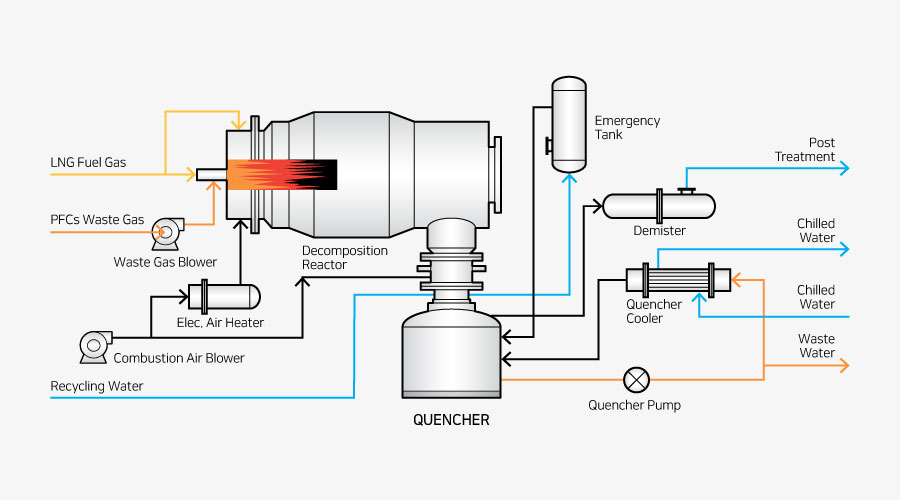

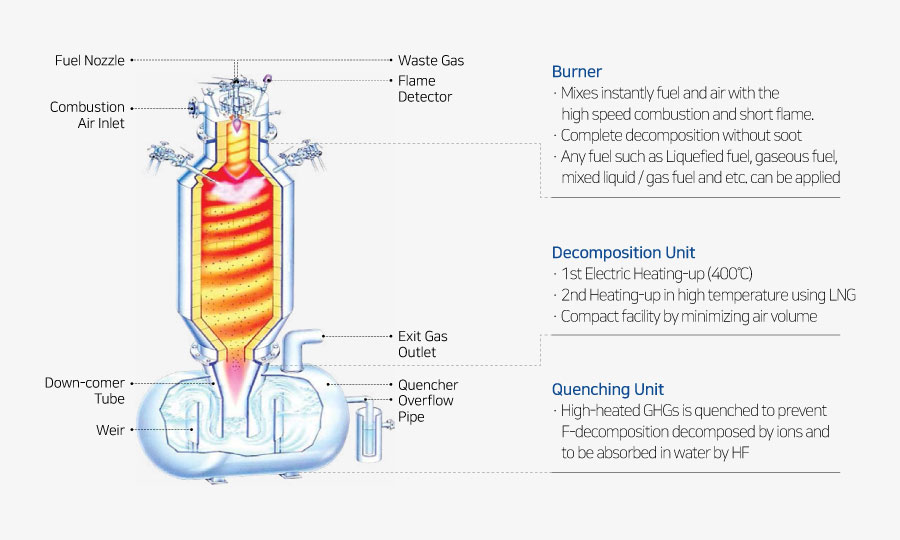

PFCs abatement system treats greenhouse gases(GHGs) such as PFC, HFC, SF6, NF3 created in semiconductor and display manufacturing processes. The GHGs generated in wet or dry etching processes contain high concentration of acid gas(HF, HCI) and ultrafine dust(0.1μm).

Daeyang E&I has proved that it can be operated continuously by using high temperature pyrolysis and rapid cooling technology to solve the corrosion problem caused during disassemble process.

In addition, rapid cooling technology can achieve high efficiency DRE (Destruction Removal Efficiency) by preventing the recombination of GHGs.

Features

- It is possible to continuously and stably remove degradable GHGs with high-efficiency.

- GHGs recombination and dioxin formation which is a secondary pollutant are prevented by rapidly cooling the high temperature gas to below 70℃.

- Facility corrosion problem is solved by converting high temperature corrosive gas into ordinary gas at room temperature with a graphite down-comer tube.

- NOx emissions are minimized by instantly mixing fuel and air with fast burning speed and short flame burner.

- The water in the quencher prevents the fire when the power is cut off, and even when the entire factory power is cut off, the PFCs gas blower is operated by the UPS power supply and the independent emergency power source, so safe discharge is possible without risk.

- Emergency water tank is provided to protect the equipment by supplying emergency water in case of water supply trouble

Process Flow Diagram

Detailed customs chart

Application Scope

- Semi-conductor and display